Innovative technologies for medical orthopaedics.

Medical

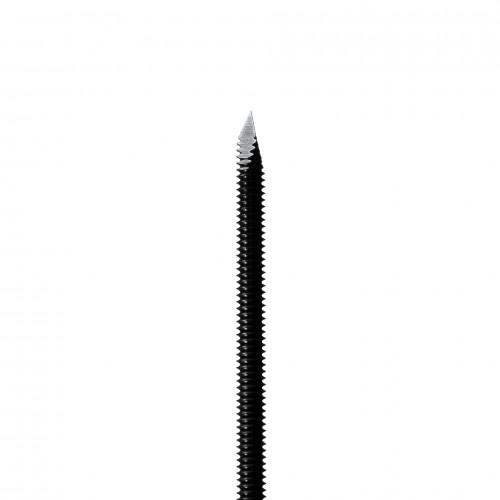

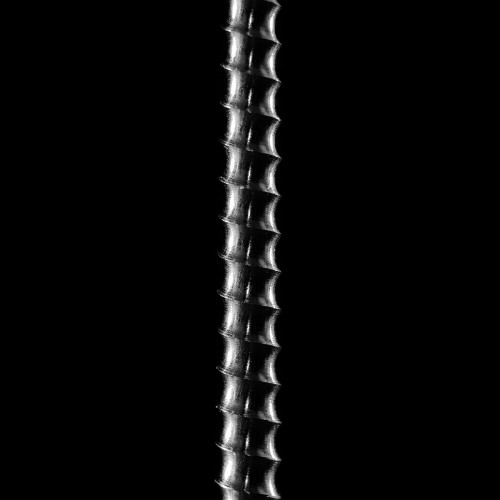

GeneralMeccanica entered the medical field as a supplier of self-tapping bone screws developing the technology and expertise needed to construct long threads featuring relatively small diameters and self-drilling drill bits.

The range of manufactured products has expanded over the years, going on to include pins, self-drilling wires, nails and various characteristic parts that are made using turning and milling technologies.

The materials used are

mainly stainless steels, in particular high resistance AISI 316 LVM ESR and Nitronic but titanium and composites are

also used.

The technology area used in

the production of these parts consists of

9 sliding-head lathes that by means of the B axis allow work to be carried

out in 5 axes,grinding of various spherical objects andup to 5 axes of sharpening.

GeneralMeccanica has the

technology to supply electropolished

and marked parts.