Technological innovation to satisfy your ideas.

Technologies

Sliding-head lathe

GeneralMeccanica

specialises in sliding-head turning for the making of parts of considerable

length and reduced diameter.

We are also capable of performing drilling operations and 5-axis milling using

sliding-head lathes, machines that allow operations to be inclined with respect

to the axis of the bar. We have 9 sliding-head lathes.

Machining centres

GeneralMeccanica has 19 machining centres of which 17 work with 4 axes. Over the years a great deal of experience has been acquired with this technology, to such an extent that we can accurately and with a high degree of performance meet the demands of the elevator and medical industries.

5-axis sharpening

To obtain the best performance from self-drilling products GeneralMeccanica uses a 5 axes sharpening system which allows us to create profiles and to grind complex geometries with a very high degree of accuracy.

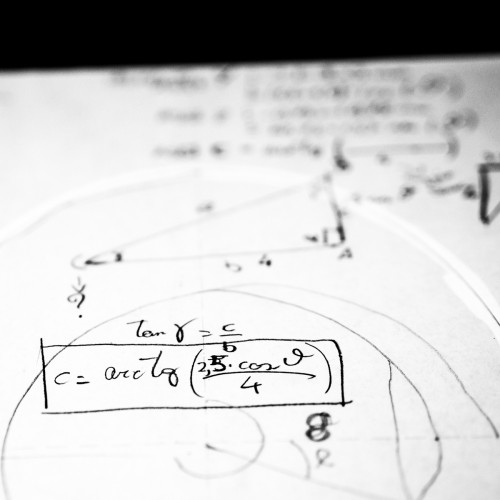

Trigonometric programming

GeneralMeccanica's

technical study engineering expertise allow us to program CNC machines using an

innovative system to create tool-paths from unconventional geometric plans.

The full use of trigonometry can often result in the substitution of CAD/CAM

programming with direct trigonometry thereby obtaining optimised and efficient

results.

Deep drilling

Thanks to numerous insights that have been perfected over the years and thanks to dedicated equipment GeneralMeccanica can achieve the drilling of lengths of up to 80 times the diameter with reduced concentricity tolerances.

Production organisation

The organisation of the production process makes use of a KanBan system to ensure Lean process management. It also is supported by an innovative computer system that reports real-time production progress, manages quality control, balanced scorecards and availability and provides other valuable information for managing various tasks.

Tumbling & deburring

In order to remove sharp edges and to obtain homogeneous surfaces products may be subjected to tumbling and deburring operations. At GeneralMeccanica this technique is employed in various ways in order to achieve various objectives, for example the smoothing of the outer surface of components in order to avoid the formation of cracks or the deburring of sharp edges.

Electropolishing and passivation

The

process of Electropolishing results in particularly smooth and shiny surfaces,

increases resistance to corrosion, removes blemishes, small superficial

inclusions and micro-cracks and increases the hygienic state of the surface.

In addition to the Electropolishing process we also have baths for carrying out

passivation operations on products.

3D measurement

At GeneralMeccanica, for dimensionally inspecting complex geometries, 3D measuring instruments are used alongside traditional ones on a daily basis.

Marking

GeneralMeccanica has the technology to perform both laser etched marking and punching.

Grinding machines for spherical and flat objects

At GeneralMeccanica we use grinding technologies for spherical and flat surfaces in order to achieve extremely regular surface finishes with controlled roughness and tolerances of < 10μm.

External technologies:

Heat treatments and galvanizing

For heat treatments such as quenching, zinc plating, burnishing and other necessities GeneralMeccanica relies on certified external Partners with whom we have collaborated for many years.